PumpGuard

Protect Machinery By Containing Solids

Trash Removal Solution for Wastewater, Stormwater and Combined Sewer Overflow

Trash Removal Solution for Wastewater, Stormwater and Combined Sewer Overflow

PumpGuard is an efficient pre-screening device that utilizes disposable mesh nets to capture solids and protect pumps, rotating equipment, disinfection systems and other machinery from potential damage by removing debris from the waste stream. PumpGuard can be designed to operate in conjunction with pump stations, between the primary and secondary clarifiers and downstream of the headwork screen.

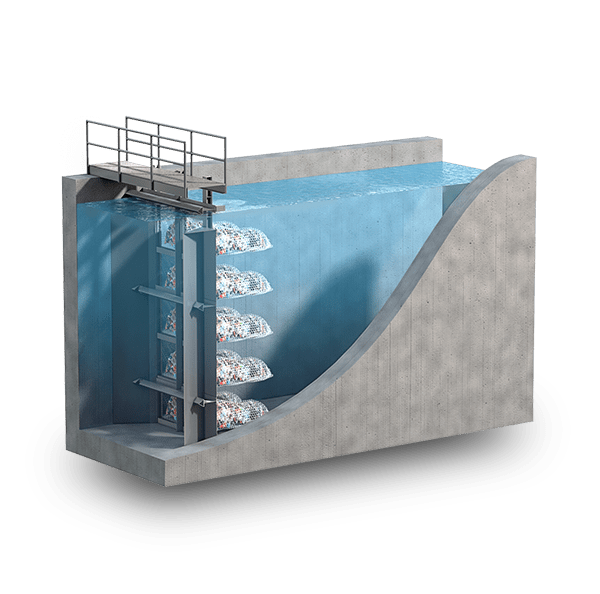

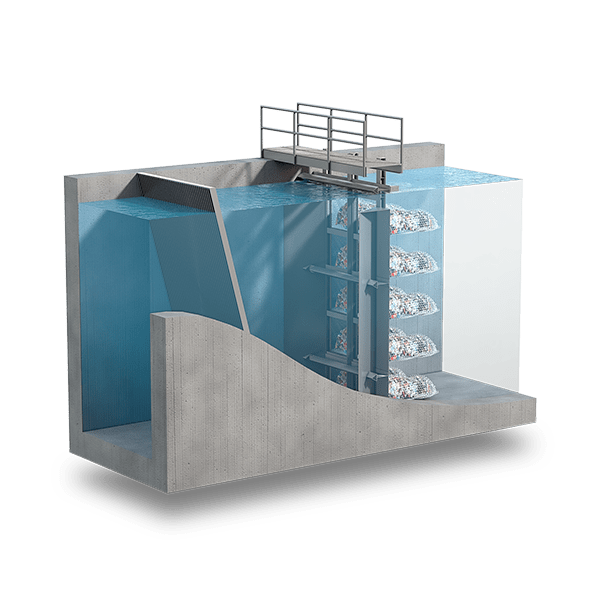

Headworks applications are installed to protect downstream equipment such as pumps and disinfection machinery. They can be placed at the headworks or downstream of the headworks of a wastewater treatment plant.

Lift station applications are installed upstream of the pumps located at lift stations to prevent suspended solids carried through the stormwater network from damaging downstream equipment.

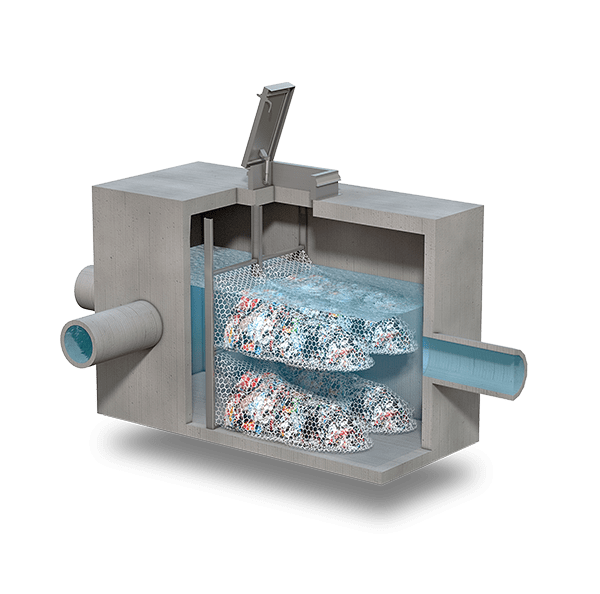

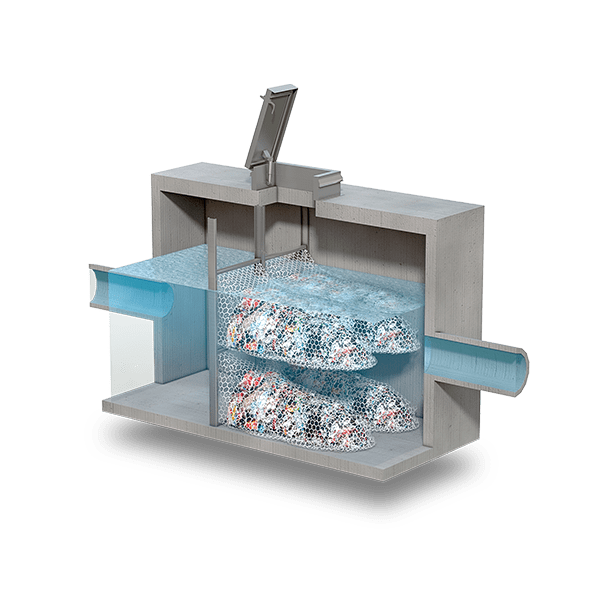

Junction chamber applications can be installed directly in a junction chamber upstream of the outlet pipe. The junction chamber PumpGuard is an excellent tool for industrial equipment because it collects pollutants within the sewer discharge before the water continues in the piping network.

This application can be installed in a precast box that connects sewer lines. The structure can be easily retrofitted in-line to the existing pipe and maintained because of the ground level access.